1 Application range

This series of relays are used in various protection and automatic control devices that require bistable contacts as a switch; at the same time, they can also be used in the tripping and closing circuit to indicate the trip and closing position of the circuit breaker.

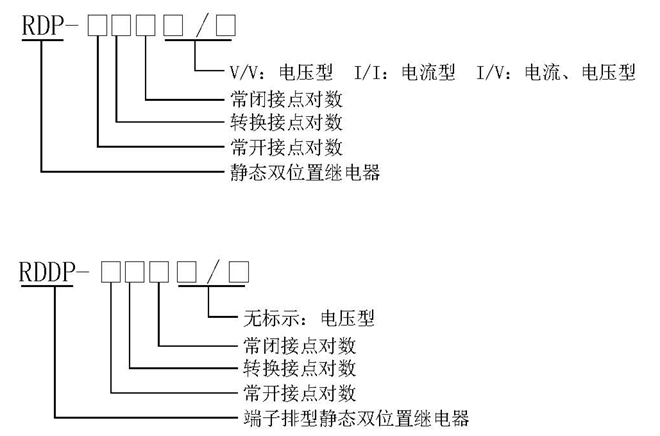

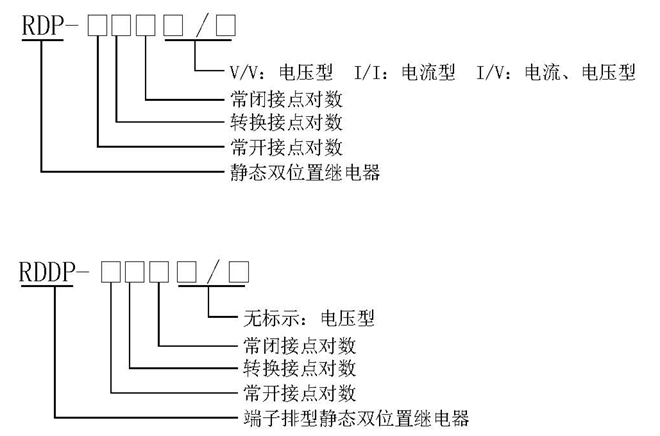

2 Model definition

3 main performance

3.1 Adopt high-performance sealed relay, moisture-proof, dust-proof, uninterrupted wire, high reliability.

3.2 The relay is bistable and magnetically maintained.

3.3 There are indicator lights indicating the closing position and the jumping position respectively.

3.4 The electrical and mechanical life of the relay is long.

3.5 High insulation withstand voltage level, large contact capacity and low contact resistance.

4 Technical conditions

4.1 Environmental reference conditions

Environment temperature: 20±2℃

Relative humidity: 45%~75%

Atmospheric pressure: 86~106KPa

4.2 Normal use conditions

Ambient temperature: -10℃~+50℃

Relative humidity of environment: not more than 90%

Atmospheric pressure: 80~110KPa

Limit temperature during storage and transportation: -25℃~+70℃

The altitude of the place of use: no more than 2500 meters

The surrounding medium of the use environment has no explosion hazard; it does not contain corrosive gas; the concentration of conductive dust contained should not reduce the insulation level below the allowable limit value.

Reliable power supply.

4.3 Characteristic parameters

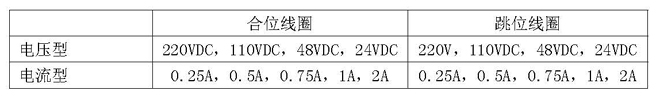

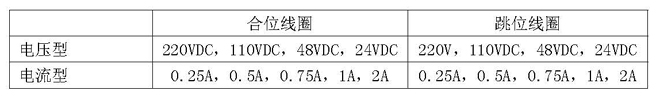

4.3.1 The ratings are as follows:

4.3.2 Action value and reset value: not more than 70% of rated value

4.3.3 Allowable fluctuation range of rated voltage: 0.8~1.15 times the rated value

4.4 Maximum power consumption

Voltage type: not more than 6W under rated voltage 220VDC

Current type: not more than 1.5W

4.5 Maximum capacity of contacts:

Cut-off load capacity: DC 250V or less, τ=5ms, inductive load 50W, resistive load 150W;

AC below 250V, load 1200VA;

Allow long-term connection current: 5A.

4.6 Insulation resistance: Use an open-circuit voltage 500V megger to measure the insulation resistance between the exposed non-charged metal parts or shells of the relays connected to each conductive terminal and should not be less than 10MΩ.

4.7 Insulation withstand voltage: each lead-out terminal to the housing locking screw can withstand a power frequency voltage of 2000V, and the same group of contacts can withstand a power frequency voltage of 1000V, which lasts for one minute without breakdown.

4.8 Anti-interference performance: Comply with the national GB6162-85 "Electrical interference test of static relays and protection devices" standard.

4.9 Electrical life: In the DC250V circuit, cut off the current τ=5ms, 50W, more than 104 times.

4.10 Mechanical life: The contact is 3 million times in no-load state.

5 Structure type (see the relay structure size diagram for details)

5.1 Embedded board rear wiring structure AK11, AP11 and protruding board front wiring AQ11 rear view wiring diagram (subject to company product samples)

5.2 DZ-2 structure terminal block type terminal wiring diagram (subject to company product samples)

6 Use

6.1 Before energizing the relay, confirm whether the voltage level and current value of the connected relay are consistent with the actual parameters, otherwise the relay may be damaged; check whether the relay is damaged during transportation and storage, and the relay screw fasteners should not be loose; There are damaged parts, please contact us to replace them.

6.2 The relay needs to be wired according to the wiring diagram. Note that the polarity of the jump coil and the close coil cannot be reversed.

6.3 The initial state of the contact in the 5th wiring diagram of the relay is the state of the jump position, and the state of the contact is opposite to the initial jump state when closed.

7 Ordering instructions

When ordering, please specify the relay model, specification, quantity, structure, voltage or current value of the double coil circuit, and other special requirements.